Rational Production DSPRO System

$0.00

Description

The DSPRO SYSTEM is the convection dissociated technology system made of the DSPRO station and the PROSERV shuttle. Designed to simplify meal distribution on trays, it allows food to be transported in a compact, lightweight, ergonomic and economical shuttle. Connecting the two elements creates the DSPRO SYSTEM, the ideal solution for heating cycles in Cook&Serve, Cook&Chill and Cook&Freeze modes. The DSPRO station is the high performance and hi-tech active system element, installed in a fixed position to run heating cycles. The PROSERV shuttle, without on-board technology, is the moving element intended to transport and distribute food.

Features:

- DSPRO SYSTEM – Catering system to simplify meal distribution on trays

- Two elements create the DSPRO SYSTEM, the ideal solution for heating cycles in Cook & Serve, Cook & Chill and Cook & Freeze modes. The DSPRO station is the high performance and hi-tech active system element, installed in a fixed position to run heating cycles. The PROSERV shuttle, without on board technology, is the moving element intended transport and distribute food.

- The use of aluframe technology, changed by the aeronautic world, has allowed the cage frame to be developed with screw joints, without welding and characterised by high sturdiness and light weight. ALUFRAME permits easy component replacement. Furthermore, the athermal profile inserts around the entire perimeter improves trolley insulation.

- Ideal solution for heating cycles in several modes:

- COOK & CHILL and COOK & FREEZE – for maintaining food cold in both compartments and regenerating the food in the hot compartments by activating the heat cycle at the appropriate moment, either manually or automatically

- COOK & SERVE – for maintaining food at the desired temperature, in both the cold and hot compartments

- Suitable for GN (325 x 530 mm), Euronorm and Extended trays (325 x 565 mm)

- Environment temperature: from 5 °C to 38 °C

- Wheels of PROSERV: 2 x Ø 160 mm / fixed 2 x 200 mm (galvanized steel)

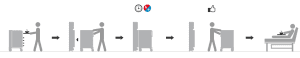

The Operating Process:

Model Variations and Capacities:

DSPRO XS + PROSERV XS

- Meal capacity: 14 trays @ 91.15 mm

- Meal capacity: 16 trays @ 79 mm

- Dimensions of DSPRO: 737 x 388 x 1528 mm

- Dimensions of PROSERV shuttle: 798 x 877 x 1071 mm

- Weight of PROSERV shuttle: 107 Kg

DSPRO S + PROSERV S

- Meal capacity: 20 trays @ 91.15 mm

- Meal capacity: 24 trays @ 79 mm

- Dimensions of PROSERV: 798 x 914 x 1393 mm

- Weight of PROSERV shuttle: 130 Kg

DSPRO S + PROSERV 3T

- Meal capacity: 36 trays @ 79 mm

- Dimensions of PROSERV shuttle: 798 x 1172 x 1393 mm

- Weight of PROSERV shuttle: 160 Kg

DSPRO L + PROSERV L

- Meal capacity: 26 trays @ 91.15 mm

- Meal capacity: 30 trays @ 79 mm

- Dimensions of DSPRO: 737 x 388 x 2066 mm

- Dimensions of PROSERV shuttle: 798 x 914 x 1629 mm

- Weight of PROSERV shuttle: 150 Kg

Downloads

For detailed product specifications and drawings, please contact Regethermic on 1300 138 026 or email us.

Additional information

| Brand | |

|---|---|

| Model | DSPRO XS + PROSERV XS, DSPRO S + PROSERV S, DSPRO S + PROSERV 3T, DSPRO L + PROSERV L |